- Details

- Category: NDT

- Published: Wednesday, 25 February 2015 16:07

- Written by Super User

- Hits: 28755

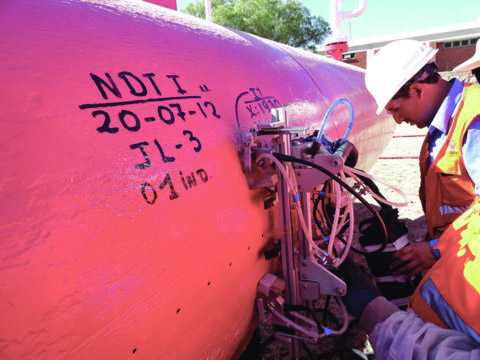

NDT Innovations has over 15 years of experience providing these services in different countries in the Americas, Europe, Asia and Australasia, supported from our main offices in United States, Australia and South America. We have been partakers of numerous projects at their different stages depending on our customer’s requirements. Our knowledge and continuous development of new solutions are the result of our dedication to product research, which has enabled us to develop innovative technologies. This approach has allowed us to attain technological advantage and efficiencies, therefore adding value to our customer’s processes and requirements.

NDT Innovations has highly trained and certified staff, as well as the best equipment to meet all the variety of services required by our customers.

NDT Innovations is highly committed to the safety of their staff and their customers through strict procedures and training of its technicians, supervisors and management personnel. Furthermore, our safety and maintenance programs have allowed us to improve the reliability and productivity, resulting in a safe and high quality service.

Why NDT Innovations?

The Quality of our work and trust in what we do is endorsed by our satisfied customers all over the world,uding Argentina, Australia, Bolivia, Brazil, Chile, China, Colombia, Czech Republic, Dominican Republic, Finland, France, Germany, Mexico, Peru, Switzerland, UK and the United States. Please refer to our Customer list for a view of our most important projects.

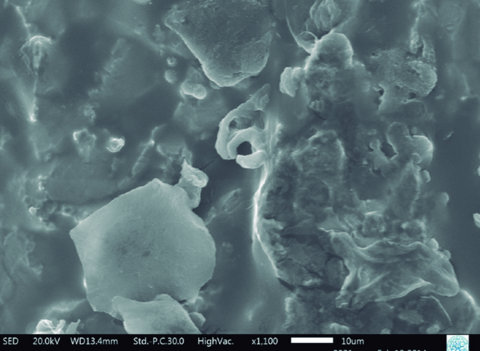

We are committed to excellence, quality and the application of the most innovative methodologies of inspection; we are proud to count with a dedicated and ongoing research team, which support us in finding practical and effective solutions for each application that our customers need.

It is our interest to know more about your company and to have the opportunity to be part of the development of your projects; we are cond that you will find that NDT Innovations will meet and surpass your expectations.

Mission:

To apply sustainable, reliable and highly innovative Inspection methods, procedures and technology within responsible industries.

Vision:

NDT Innovations is devoted to excellence in all aspects of Materials Inspection.

Quality Policy:

In NDT Innovations we are dedicated to providing highly innovative non-destructive testing services that help us provide personalized, reliable, differentiated and sustainable solutions, which allow us to achieve results with the highest quality.

We are highly committed to providing our services with excellence and quality. click for document.